The operators at the floating production, storage, and offloading (FPSO) facility faced a challenge in improving team productivity and efficiency for continuous tank cleaning. They had been using an outdated bucket and winch approach for tank sludge removal and cleaning, which limited them to filling only three tanks with two crews and winches during a whole day shift. It led to high costs due to operational downtime but also involved intensive manual work in hazardous environments.

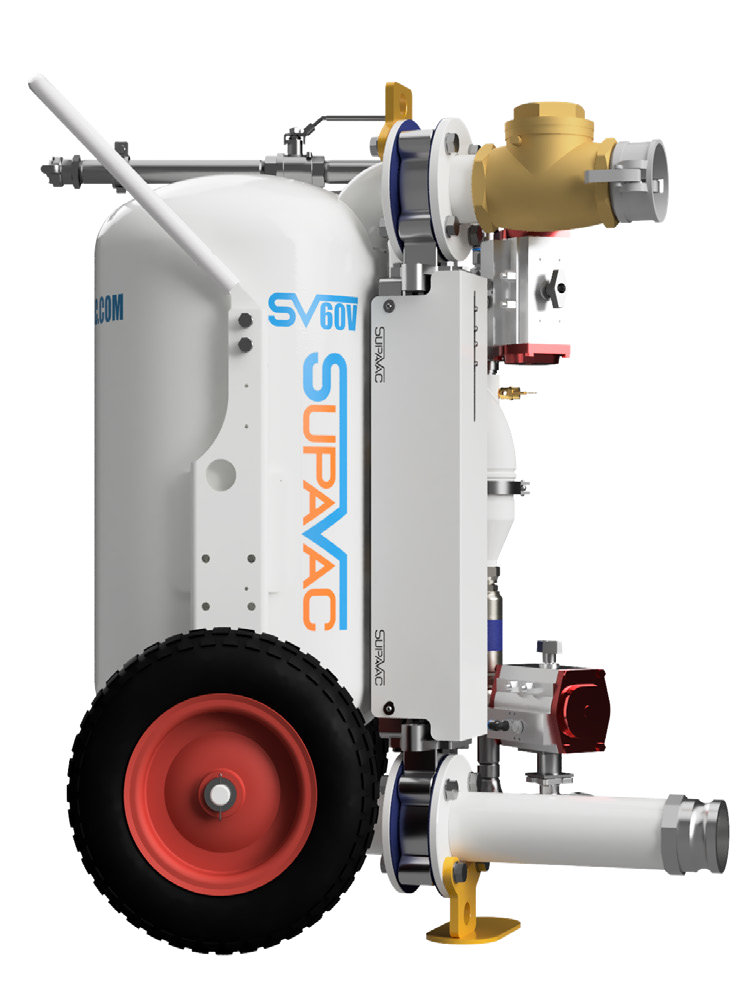

The solution for FPSO Tank Cleaning was the implementation of three SupaVac SV60-V2 Portable Solids Pumps configured with vent-to-atmosphere. The units are portable by design and were easily lowered 30 meters into the tank through tight access hatches. They efficiently pumped solids upward over 30 metres to the top deck, which helped improve transfer efficiencies. The vertical hosing setup reduced downtime and power requirements, plus the enhanced safety features of the LPD discharge pressure for pumping sludge from various tank areas.

The solution for FPSO Tank Cleaning was the implementation of three SupaVac SV60-V2 Portable Solids Pumps configured with vent-to-atmosphere. The units are portable by design and were easily lowered 30 meters into the tank through tight access hatches. They efficiently pumped solids upward over 30 metres to the top deck, which helped improve transfer efficiencies. The vertical hosing setup reduced downtime and power requirements, plus the enhanced safety features of the LPD discharge pressure for pumping sludge from various tank areas.

The SupaVac units were a consequential improvement over the traditional FPSO operators’ sludge removal method. The team achieved a clean-out rate of 7-10 daily tanks per crew. Feedback from the customer confirmed that these SV60-V2 SupaVac units substantially decreased the timeframe for sludge removal, now requiring only half the power compared to previous operations. The benefits included a 50% reduction in onsite personnel requirements and a remarkable 650% acceleration in tank cleaning.

For more information on our extensive SupaVac products range and to request a quote, call Dynapumps on 1300 788 579 or email sales@dynapumps.com.au.