A Wastewater Treatment Plant faced the challenge of accommodating a growing population while adhering to increasingly stringent regulations and environmental concerns. To address these issues, they sought ways to optimise and future-proof their operations.

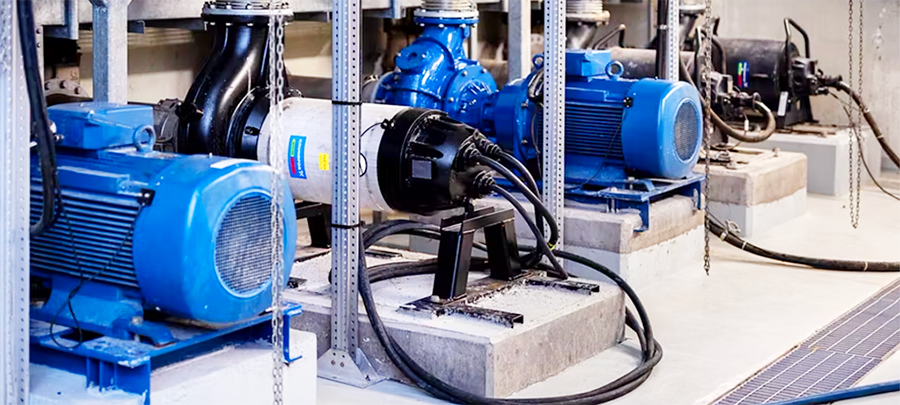

At the pumping station, a 75 kW pump was one of five used to transport water to the treatment plant. However, due to rising levels of solids in the wastewater, this pump frequently clogged, requiring several hours of manual unclogging by staff. Moreover, the energy consumption of the 75 kW pump was higher than desired.

As part of a field test of the new SE/SL Range 56 wastewater pumps, it was suggested that a 63 kW Grundfos SE pump featuring the innovative Open S-tube impeller design be trialed. This design aims to prevent clogging and enhance efficiency at the installation. Thanks to its excellent self-cleaning capabilities, the 63 kW SE pump can effectively manage wastewater with sediment while consuming less energy than the old pump and eliminating clogging issues.

As part of a field test of the new SE/SL Range 56 wastewater pumps, it was suggested that a 63 kW Grundfos SE pump featuring the innovative Open S-tube impeller design be trialed. This design aims to prevent clogging and enhance efficiency at the installation. Thanks to its excellent self-cleaning capabilities, the 63 kW SE pump can effectively manage wastewater with sediment while consuming less energy than the old pump and eliminating clogging issues.

The Grundfos Open S-tube impeller is specifically engineered to prevent clogging. Its semi-open impeller blades are designed to work in conjunction with an adjustable suction cover equipped with a spin-out groove, which ensures that fibers are efficiently transported away with the sewage water. This design prevents sediment accumulation and guarantees a continuous flow of solids toward the pump discharge, optimising the process for maximum efficiency.

After two and a half years of testing, the results at the pumping station have been impressive. The new pump has not experienced a single clogging incident, making daily operations more efficient and hassle-free. Additionally, it has led to energy savings of over 30,000 kWh per year, reducing costs and effectively resolving the clogging issues for the Wastewater Treatment Plant.